Nitrile gloves are one of the best options for those in the medical field who are looking for an effective way to protect their hands. But how are nitrile gloves manufactured? This article will show you everything about manufacturing nitrile gloves and more.

About Nitrile Gloves

Nitrile gloves are made from synthetic nitrile and they are designed to resist punctures. They are also resistant to chemicals, oils and other materials that have the potential to cause harm to the user. Nitrile gloves are usually dark blue, light blue and come in a variety of sizes.

Nitrile gloves were first patented in the year 1937, but they were not widely used until the 1980s. The reason for this is because they were not as durable as latex gloves, and they also did not provide the same level of protection against punctures and chemicals. It wasn’t until nitrile gloves were improved that they began to be used more frequently in the medical field.

There are many benefits to using nitrile gloves in the medical field. One of the main benefits is that they are effective in keeping out harmful chemicals, bacteria, blood and other materials. Nitrile gloves are more resistant to punctures, which is important for those who use needles or other sharp objects.Another benefit of nitrile gloves is that they are less likely to cause an allergic reaction than latex gloves.

How Are Nitrile Gloves Manufactured?

Nitrile gloves have very good physical properties and chemical resistance. They are comfortable to wear and rarely cause skin irritation. They are often used in medical, food processing, food service, daily cleaning, printing and dyeing, laboratory and electronics processing applications. With their many benefits, nitrile gloves are arguably the leading disposable protective gloves. So how do nitrile gloves come about? Let’s take a look at the production process of nitrile gloves.

Nitrile gloves are mainly made by impregnating nitrile rubber, moulding, vulcanising, surface treatment and dust-free cleaning. The specific production processes are as follows.

1. Preparation of raw materials

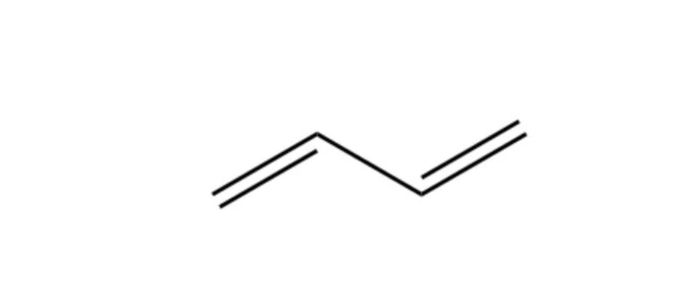

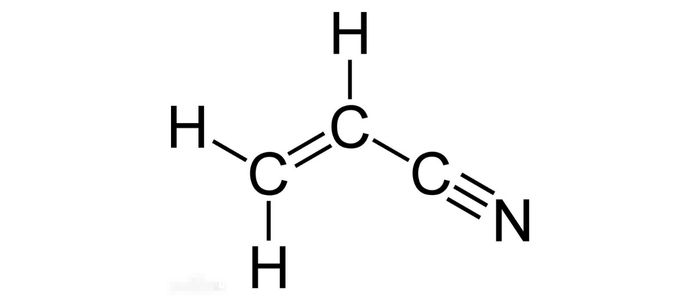

Firstly, the raw material used to manufacture nitrile gloves is nitrile rubber, which is made from the emulsion polymerisation of butadiene and acrylonitrile. All these raw material solutions are first poured into a large container.

2. Washing the hand film

Then, the hand moulds are cleaned and, after washing them, they should be dried before moving on to the next step.

3. Dipping

The third step is to dry the hand film after it has been dipped into the container containing the nitrile raw material, heated by high temperatures and formed into a glove.

4. Rolling the edges

Next, we need to prepare the gloves for curling to facilitate putting on and taking off the gloves.

5. Chlorine wash

After these steps, the nitrile gloves have been formed but are not yet successful and need a key step: a chlorine wash. Chlorine cleaning removes the stickiness from the surface of the glove, making it softer and smoother, which is an important reason why nitrile gloves are so easy to wear.

Finally, the nitrile glove is separated from the hand mould and a pair of gloves is produced.

This process is not straightforward as there are many steps in the manufacture of nitrile gloves. However, it is important to understand the manufacturing process of these gloves so that you can be sure that the product you are using is safe and effective.

Characteristics of Nitrile Gloves

1. Material

Nitrile gloves are made from a variety of different materials, but the most common material is nitrile rubber. The advantages of this type of rubber are Good oil resistance. Oil resistance is the number one advantage of nitrile rubber and is even much superior to that of SBR, natural rubber and neoprene among general purpose rubbers.

Good antistatic properties. NBR has excellent antistatic properties and is therefore used in a large range of cables.

Abrasion resistance. The density of nitrile rubber is high, and in the process of being reinforced with rubber, the abrasion resistance of nitrile rubber is strengthened. This ensures the longevity of the nitrile rubber.

2. Sizes

Nitrile gloves come in a variety of sizes, but the most common sizes are small, medium and large. If you require a smaller size or a larger size, SOSUN Glove Factory can customise the size you require. This is because nitrile gloves are designed to fit snugly on the hand, and they need to fit snugly to be effective and more flexible to use.

3. Colours

Nitrile gloves also come in a variety of colours, but the most common colour is blue. This is because blue nitrile gloves are designed to change the colour difference. Blue is a colour that is well distinguished from blood and is now used not only in operating theatres, but also in many places where blue nitrile gloves are necessary for some of the more dangerous jobs, such as, chefs, electronics factories, chemicals, etc. Blue nitrile gloves can be used in colours to alert staff to change gloves and reduce the chance of infection.

How to Choose the Right Nitrile Disposable Gloves

When choosing nitrile gloves, you need to consider a number of factors. Some of the things you need to consider include.

The type of material the gloves are made from

Nitrile gloves are available in two types: medical and non-medical. Medical nitrile is generally used in places such as hospitals and clinics where people are exposed to viruses, bacteria, blood and other infectious materials; so they need to be protected with sterilised nitrile gloves.

Non-medical gloves can be used for general everyday use, such as food handling, household cleaning and gardening.

Size of gloves

The size of the glove is also important as you need to make sure that it fits snugly into your hand. If the gloves are too loose, they will not protect you effectively from punctures and chemicals, which will also affect your efficiency at work.

Thickness of gloves

The thickness of your gloves is also something you need to consider. Nitrile gloves are also available in thicker versions, mainly for use in jobs that are prone to wear and tear, so choose wisely according to your usage scenario.

It is important to consider all of these factors when choosing nitrile gloves so that you can choose the right glove for your needs.

FDA Standard

The nitrile gloves that are used in the medical field must meet certain standards in order to be effective. These standards are set by the FDA, and they help to ensure that the gloves are safe for use.

Some of the standards that the FDA has set for nitrile gloves include:

1.The gloves must be made from a material that is safe for use

2.The gloves must be free of any defects

3.The gloves must be able to resist punctures and tears

4.The gloves must be able to protect against harmful chemicals and other materials

Nitrile gloves are an essential part of the medical field, and they play a vital role in protecting both patients and medical professionals. It is important to choose gloves that meet the FDA’s standards so that you can be sure that you are using a product that is safe and effective.

Glove Testing

Before you can use nitrile gloves, they need to undergo a series of tests to ensure that they are safe and effective. Some of the tests that nitrile gloves need to pass include:

Puncture resistance test

This test ensures that the gloves can withstand sharp objects.

Abrasion resistance test

This test measures the strength of the gloves.

Chemical resistance test

This test ensures that the gloves can protect your hands from dangerous chemicals.

Tensile strength test

This test measures the strength of the gloves.

All of these tests are important in ensuring that nitrile gloves are safe and effective. Without these tests, it would be impossible to know if nitrile gloves are the right choice for you.

These tests are designed to ensure that nitrile gloves can protect your hands from a variety of dangers. It is important to choose gloves that have passed all of these tests so that you can be sure that you are using a product that is safe and effective.

What a Nitrile Glove Protects Against

Nitrile gloves are designed to protect your hands from a variety of dangers. One of the most common uses for nitrile gloves is to protect your hands from chemicals.

Nitrile gloves are also used to protect your hands from punctures and cuts. They are also used in the food industry to protect against contamination.

Moreover, nitrile gloves are an essential part of many industries, and they play a vital role in protecting both workers and consumers. It is important to choose the right nitrile gloves for your needs so that you can be sure that you are using a product that is safe and effective.

Conclusion

Manufacturing nitrile gloves can be a long process, but it is important to ensure that the gloves are safe and effective. The process starts with testing the raw materials for purity and quality. Once the raw materials have been approved, the manufacturing process can begin.

The manufacturing process is closely monitored to ensure that the gloves meet all of the necessary safety standards. After the gloves have been manufactured, they are sent to a third-party laboratory for testing.

When choosing a nitrile gloves factory manufacturer, it is important to choose a company that takes the time to test their products. Only by choosing a company that takes the time to test their gloves can you be sure that you are using a product that is safe and effective.