Latex gloves have long been popular power players among disposable gloves, whether they’re powdered latex gloves or powder-free gloves. Also,the material are made from natural latex, it is biodegradable and environmental protection.

Cause the unique raw materials, latex remains comfort, stretchiness, and tactile sensitivity. This makes latex a popular compound among a specific population: the medical situation.

In terms of medical gloves–especially surgical gloves–few materials can match the dexterity and tactile sensitivity of a latex glove. This is incredibly important for work requiring extreme precision, such as surgery. That said, even regular physicians remain frequent users of latex gloves. Even a regular physical exam needs tactile sensitivity, and on that front, latex gloves are hard to beat.

Latex is also quite popular among workers who need frequent glove changes, whether that’s the healthcare industry or elsewhere. In many cases, you would need powdered gloves to provide the same comfort level as latex powder-free gloves.

For this reason, latex is also popular among laboratory workers. It does quite well with most biological agents, though natural rubber does not perform well around certain solvents.

The rubber is first sliced by a rubber mixer, and then sent to a sol tank to mix the sol with gasoline. The sol is then emulsified and modulated and then pumped to the latex intermediate tank. The rubber solution dissolved in gasoline is fed from the top of the distillation tower, heated and distilled by steam, the light component gasoline is heated into a gas phase, and the gasoline gas is mixed with cold water in the oil and gas cooler and cooled. The oil-water mixture is then sent to the oil-water separator, and the oil-water layer is separated. The upper layer gasoline is recovered, the lower water is pumped to the cooling water tower for cooling, and then the gas gasoline in the distillation tower is cooled after cooling; the latex in the distillation tower kettle is sent to the latex mixing tank to be stirred according to its own pressure, and after modulation, the glove raw material latex is separated by the centrifuge. After toning and filtering, it is ready for use.

The glove model is first cleaned with acid and alkali and washed with water. The cleaned model is first immersed in hot water and heated, then dipped in coagulant and dried for dipping. After dipping, it is sent to the oven for preliminary drying, the fiber inner sleeve is added, and the hot water is sent to the oven for vulcanization, drying and molding. After the gloves are demolded, they are inflated for inspection, shaped at low temperature, dried at medium temperature, washed with water, dehydrated, dried, and then packaged and sent to the finished product warehouse.

| Name | Latex Gloves |

|---|---|

| Material | Natural Latex |

| Types of gloves | Industrial, Food, Medical |

| Color | Milk White,Natural White |

| Model Number | S,M,L |

| Specification | 9Inches |

| Standard Weight(±0.3g) | S-5g |

| M-6g | |

| L-7g | |

| Elongation Rate% | ≥650% |

Latex gloves not only have the advantages of wear resistance, wear resistance, softness and high elasticity, but also are resistant to acid and alkali, grease and various solvents; they are not only soft in texture, fit the shape of the hand, but also comfortable to wear without affecting the flexibility of the hand; Made of natural rubber, it is non-toxic, harmless and easy to degrade. It can be dissolved in nature quickly after being discarded, which has very important environmental protection significance. It has good sealing performance and strong elasticity, and can be used for high-risk contact with blood or body fluids. non-sterile manipulations, manipulations involving sharps, manipulations of cytotoxic substances and disinfectants.

Latex gloves have strong elasticity fitting hands comfortable,Suitable for hospital,clinic beauty medicine, automobile manufacturing, battery manufacturing; glass fiber reinforced plastic industry, aircraft assembly; aerospace field,environmental cleaning and cleaning works.

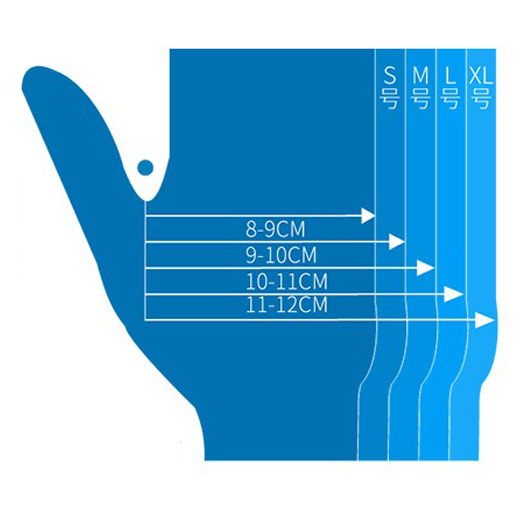

According to the hand type code selection,

Measurement method: Straighten the palm, connect the thumb and index finger to the outside of the palm, and measure the palm width to obtain the width of the palm, and select the corresponding size.

Hand width 8-9CM-please choose size S

Hand width 9-10CM-please choose size M

Hand width 10-11CM-please choose size L

Hand width 11-12CM-please choose size XL

Remarks: The actual width must be based on the scale of the ruler, and the width of the thumb is not counted when measuring.

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right medical products you want.